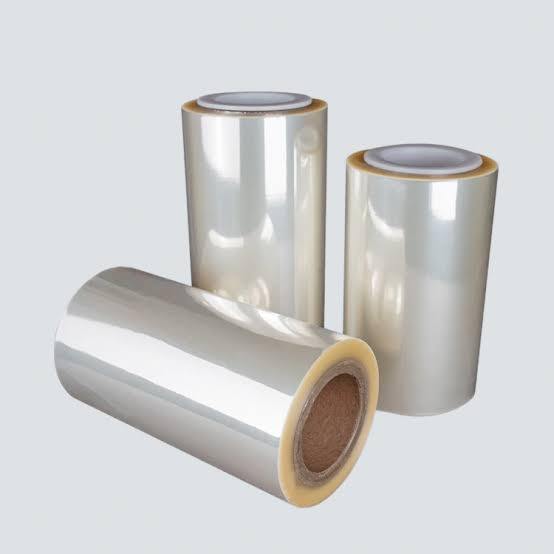

PVC HEAT SHRINK

PVC HEAT SHRINK Trade Information

- Minimum Order Quantity

- 1000 Kilograms

- FOB Port

- MUNDRA

- Supply Ability

- 20000 Kilograms Per Week

- Delivery Time

- 10 Days

- Sample Available

- No

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- AS PER CUSTOMER REQUIREMENTS

- Main Export Market(s)

- Asia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About PVC HEAT SHRINK

PVC Heat Shrink Tubing Specifications

PVC heat shrink tubing comes in a variety of sizes, colors, and grades. Below are the general specifications for standard PVC heat shrink tubing. These can vary depending on the manufacturer and intended application (e.g., general electrical use, automotive, etc.), but the core features remain relatively consistent.

1. Material Composition

- Base Material: Polyvinyl Chloride (PVC)

- Additives: Plasticizers, stabilizers, and colorants may be added for flexibility, durability, and color coding.

2. Shrink Ratio

- Shrink Ratio: 2: 1 (common), meaning the tubing will shrink to approximately half of its original diameter when heat is applied.

- Some high-performance PVC heat shrink tubing may have a 3: 1 shrink ratio, offering even more versatility.

3. Temperature Range

- Shrink Temperature: The tubing starts shrinking at temperatures of approximately 120C (248F).

- Continuous Operating Temperature: Typically up to 85C to 105C (185F to 221F).

- Short-Term Maximum Temperature: PVC heat shrink can tolerate up to 125C (257F) during installation and heating.

4. Wall Thickness (After Shrinking)

- The wall thickness after shrinkage can range between 0.25 mm to 0.5 mm (0.01 in to 0.02 in), but this depends on the initial size of the tubing and its shrink ratio.

- Thicker wall options (e.g., 1.0 mm or more) are available for higher-strength protection.

5. Size Range (Inner Diameter)

- Available Diameters: PVC heat shrink tubing is available in a wide range of sizes, from very small diameters (1 mm or less) for tiny wires, to larger diameters (up to 100 mm or more) for covering larger cables and connectors.

- Common diameters include:

- 1 mm 50 mm for cables and wires

- Larger sizes (up to 100 mm or more) for industrial applications

6. Shrinkage Rate

- Typical Shrinkage: 50% in diameter, meaning it reduces its diameter to half when heated.

- Length Shrinkage: Generally, the length of the tubing does not shrink significantly, typically shrinking by around 5% to 10%.

7. Dielectric Strength

- Voltage Rating: PVC heat shrink tubing typically offers good insulation properties, with a dielectric strength of 10-15 kV/mm (kilovolt per millimeter) depending on the tubings thickness and manufacturer.

- This makes it suitable for electrical applications where insulation is necessary.

8. Flame Retardancy

- Flame Retardant: Many PVC heat shrink tubes are designed to meet flame retardant standards, reducing the risk of fire in hazardous environments.

- They often comply with UL 224 (Standard for Electrical Insulation) and UL 94-V0 for flame resistance.

9. Chemical Resistance

- PVC heat shrink has moderate resistance to chemicals, oils, water, and environmental factors, but is less resistant to extreme chemicals or solvents compared to other materials like fluoropolymer-based heat shrink tubing.

- Resistant to: Weak acids, oils, and some solvents.

- Not suitable for: Strong acids, alkalis, and solvents like acetone.

10. Flexibility and Bend Radius

- PVC heat shrink tubing is moderately flexible once shrunk, though it is generally stiffer than polyolefin-based tubing.

- Minimum Bend Radius: It typically requires a minimum bend radius of 1.5 to 2 times the diameter of the tubing.

11. Color Options

- Available in a wide range of colors for identification purposes, such as:

- Black

- Red

- Blue

- Yellow

- Clear

- Other colors are available for specialized applications.

12. Certifications and Standards

- UL 224: Standard for Thermoplastic Insulating Tubing (for electrical insulation).

- RoHS Compliance: PVC heat shrink tubing is typically RoHS (Restriction of Hazardous Substances) compliant, ensuring it is free of harmful substances like lead and mercury.

- ISO 9001: Many manufacturers follow ISO standards for quality control in production.

13. Applications

- Electrical Wiring Insulation: Protects wires and cables from environmental damage, abrasion, and short circuits.

- Connector Insulation: Commonly used to insulate connectors and splices.

- Strain Relief: Provides support to prevent strain on sensitive wire connections.

- Identification: Used in color-coding cables and wires for easy identification.

- Automotive and Industrial Wiring: Provides reliable protection in harsh environments.

- General Purpose: Suitable for consumer electronics, electrical devices, and various industrial sectors.

14. Packaging

- PVC heat shrink tubing is often sold in spools, pre-cut lengths, or dispenser boxes depending on the supplier and application.

FAQs of PVC HEAT SHRINK:

Q: What is PVC Heat Shrink used for?

A: PVC Heat Shrink is used for packaging purposes.Q: What is the color of PVC Heat Shrink?

A: PVC Heat Shrink is available in all colors.Q: What is the purity percentage of PVC Heat Shrink?

A: PVC Heat Shrink has a purity percentage of 100%.Q: What type of material is PVC Heat Shrink made of?

A: PVC Heat Shrink is made of plastics.Q: What grade of PVC Heat Shrink is available?

A: PVC Heat Shrink is available in food grade.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS